After approving the initial estimate, we will schedule an appointment so that we can come to the jobsite to take exact measurements. Due to the nature of field measurements, we will give a 2 hour time window for this appointment.

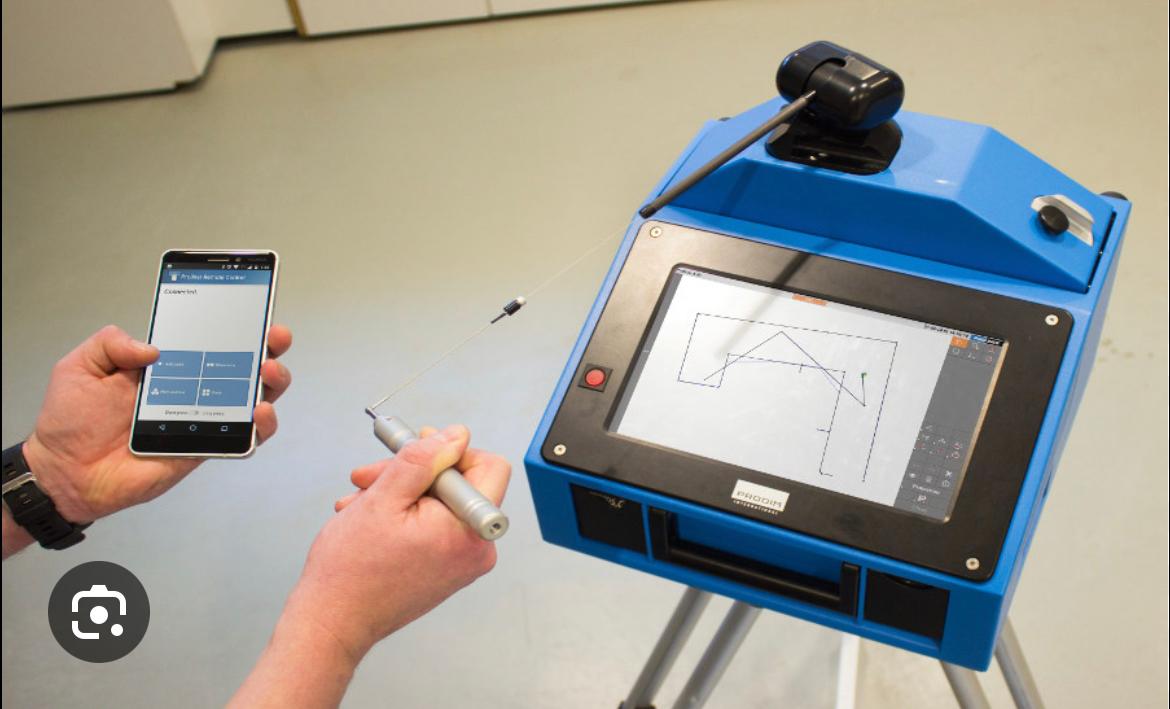

As every other step of the process, we use the latest and the most accurate technology available for templating. Our measurer takes precise measurements by a laser templator. This device calculates the distances by shooting a laser beam to the desired targets. These distances are then converted to a CAD (Computer Aided Drawing) file displayed on the laptop computer screen which is a part of the templating machine. The measurer creates a pattern of the cabinets and for the entire surface area where stone will be applied using the laser templator. The laser technology allows us to prevent any mistakes. These templates are used in the fabrication of the countertops with any shapes from the simplest rectangle to the most complicated designs. Utilizing the laser technology we are also able to fabricate the countertops precisely scribed to the walls.

Just like with everything else, preparation is critical when it comes to installing a countertop. That’s where templating comes in. Templating is the process of creating a template that will allow a fabricator to know the exact measurements of a new countertop.

Originally, countertop templating was the manual designing and building of a physical model to scale using cheaper materials before the installation of the countertop.

In the 1990s, the introduction of laser templating changed everything. Human error is no longer part of the equation, as advanced laser technology helps make templates with precise measurements.

The difference is simple – laser measurements are more accurate. While the old way of measuring doesn’t account for human error, laser measuring eliminates it. There may not be a huge discrepancy when it comes to measuring a perfectly square island, but when there are rounded. However wavy edges with abnormal angles to consider, laser measurements are a huge advantage.

What do “perfect measurements” look like? When it comes to creating the tightest, most quality fit, the measurements have to be exact, down to the fraction of an inch. And while manual measurements can come close to accurate, they won’t be nearly as precise as laser measurements.

Capturing the data and measurements of a countertop with a laser has huge advantages. Granite, quartz, and porcelain countertops are durable and beautiful, but it’s pivotal to make sure the cut is accurate the first time. It is challenging to adjust a cut if it’s not done precisely the first time.

Capturing the data and measurements of a countertop with a laser has huge advantages. Granite, quartz, and porcelain countertops are durable and beautiful, but it’s pivotal to make sure the cut is accurate the first time. It is challenging to adjust a cut if it’s not done precisely the first time.

Removes guesswork – You’re in control. While the laser sends information to the computer, the technician can add additional information. This information includes specifics about backsplashes, specialty cuts, or cutouts for sinks and faucets.

Fast and efficient – While manually designing and building a template could take a significant amount of time, laser templating is far more efficient, taking less time to complete. Improves accuracy of cutting – Precise measurements mean precise cutting. Laser measuring precisely captures the specific shape of the countertop, accounting for any waviness or bows in the walls, which ensures a perfect fit.